Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewBuy

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

OverviewEDI (Electronic Data Interchange)

Overview- Home

- Smart MechatroniX

- Smart Function Kits

Coordinated mechatronic subsystems for a wide range of automation requirements

Smart mechatronics for handling and pressing

Selecting, configuring, commissioning and programming subsystems for assembly, handling, dispensing or joining tasks does not need to be a monotonous, laborious process. With our smart mechatronic solutions, we simplify not only engineering but also commissioning and the production of programs for a wide range of automation processes. Are you ready?

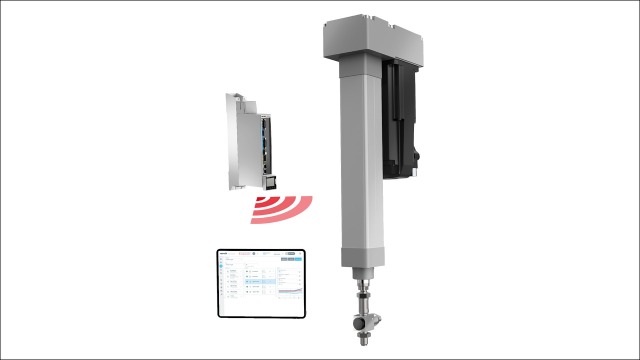

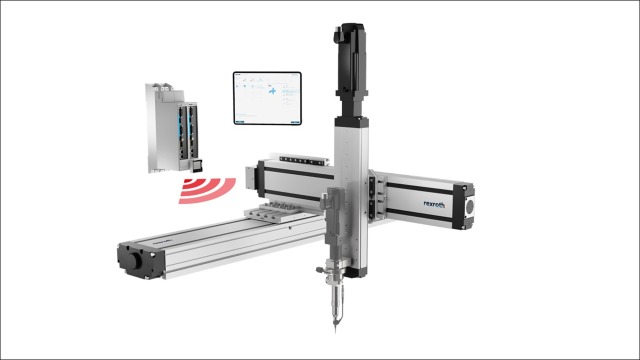

Mechatronic systems for linear robotics: Smart Function Kits

Fast, simple, intuitive: Our ecosystem with predefined systems combines mechatronic, drive and control solutions and software. It can be used in a variety of areas – thanks to compatible end effectors and open interfaces.

Everything fits seamlessly together. From handling systems based on linear axes to servo presses, Bosch Rexroth provides ready-to-install mechatronic subsystems with suitable automation hardware and pre-installed software. They allow quick commissioning and simple graphical programming.